JLG Industries

ForgeFX Simulations is a proud simulation development partner of JLG Industries, an Oshkosh Corporation company, and the world’s largest designer, manufacturer and marketer of access equipment (aerial work platforms, telehandlers, scissor lifts and other access equipment). In addition to creating industry-leading equipment, JLG partners with their customers by providing cutting-edge training, which is unsurpassed in the industry. The huge success JLG has achieved also presents them with a challenge, how to provide training for such a large number of new operators. To meet this challenge JLG partnered with ForgeFX to develop AccessReady Fusion XR™, a virtual reality access equipment training simulator that allows trainees to learn proper operation, in a safe and risk-free virtual environment. This boom lift training simulator was the first piece of equipment to be simulated for this access equipment training simulator product, and its success led to the addition multiple machine types into the simulator.

AccessReady Fusion XR Training Simulator

JLG Industries, AccessReady XR™ Virtual Reality Training Simulator

AccessReady Fusion XR is an advanced training tool that allows operators to safely work in challenging, real-world situations to develop their skills. This virtual reality training package brings the job site environment, access equipment and required skills together in an easy-to-use format. It’s a great option for rental companies and AccessReady trainers looking to give their trainees more hands-on training time. The JLG AccessReady Fusion XR™ access equipment training simulator helps operators to quickly, and safely, become comfortable and gain proficiency with nbsp; equipment controls, allowing them to be better, faster, and safer operators in the real world.

JLG Industries AccessReady Fusion XR™ Virtual Reality Equipment Training Simulator

JLG is dedicated to helping their customers increase productivity and lower operating costs. Their 800 Series Telescoping Boom Lift takes you from the ground to 80 feet in less than 67 seconds, with a horizontal outreach of up to 75 feet. JLG’s telescoping boom lifts take you from the ground to full extension in just over a minute, with horizontal outreaches up to 80 feet. Achieving proper training is essential in order to correctly and safely operate aerial work platforms. JLG’s AccessReady Fusion XR™ delivers highly interactive and immersive virtual reality-based simulation training to help produce the highly-trained operators.

JLG AccessReady XR™ Virtual Reality Training Simulator Developed by ForgeFX Simulations

ForgeFX is proud to have developed this virtual reality training simulator for JLG Industries. The JLG equipment simulator provides VR-based training for operators of all skill levels, teaching everything from controls familiarization, to machine operation, to advanced spatial awareness challenges. ForgeFX Simulations produced a training simulator framework for JLG that is available across a collection of platforms and devices, including Virtual Reality, Windows, iPad, etc., allowing operators to easily access the comprehensive simulation-based training content wherever they are. AccessReady Fusion XR™, now available for purchase from JLG Industries, provides operators with a virtual reality-based training simulator, including everything from machine controls familiarization, to task-based scenarios for training on complex maneuvers, to a networked multi-user instructor-led modes.

Introducing the JLG® AccessReady Fusion XR™ Virtual Reality Training Simulator

AccessReady XR: Virtual Reality Training from JLG

Introducing the JLG® AccessReady XR™ Virtual Reality Training Simulator

Unboxing the AccessReady XR™ Training Simulator from JLG

Train in Multiplayer Mode with the JLG® AccessReady XR™ VR Simulator

Share Your JLG® AccessReady XR™ Experience

JLG 800S Aerial Work Platform Virtual Reality Training Simulator

Training Simulators Increase Productivity

At their facility in McConnellsburg, PA, JLG has created a testing and training facility that duplicates many aspects of a typical real-world job site. For example, uneven surface, mock buildings under construction, and a variety of loads to transport. To train on site with experts at the proving grounds is an invaluable experience. However, the real-world proving grounds can’t handle the volume, nor can everyone handle the expense of on-site travel and training. In the JLG Equipment Simulator, ForgeFX has created a true-to-life replica of the Proving Grounds, allowing an unlimited number of students to gain much of what is gained in the real-world experience.

JLG’s HTC VIVE Pro Training Simulator by ForgeFX Simulations

The Simulated World Offers Options the Real World Cannot

The virtual training experience offers operators some things you can’t experience in the real-world. For example, within the simulation an operator can see an exterior, or bird’s eye view, of the effects of control manipulations as they are using the equipment. This allows trainees to not only learn how to operate the machine, but also to understand the spatial awareness challenges they’ll face when operating equipment in the real-world. As a novice user extends the boom arm he can switch to a dedicated virtual camera which shows how much room he has left, allowing him to gain a feel for the limits of what is possible.

JLG Industries Access Equipment Training Simulator

Studying Boom Lift Operations

The first step that ForgeFX takes when embarking on an operator training simulation development project for any piece of equipment is to study that equipment in operation in the real-world. The ForgeFX team brings on site every type of media capture device imaginable: SLR still cameras, audio recording equipment, and video recording equipment. The capture process for boom lifts which can operate 185 feet in the air posed a unique challenge. To meet this challenge, ForgeFX used drone-mounted aerial cameras in order to closely observe the actions of veteran operators at altitude.

JLG Immersive Training Simulator Task-Based Scenarios

Capturing and studying exactly how booms work can be a challenge. For example, the 1850 can operate 185 feet in the air. For all of our clients, ForgeFX begins the project with an onsite visit where we record many hours of raw source footage. This footage is then edited and cataloged for use as a reference during the simulation development process. ForgeFX brings everything to bear to capture every aspect possible.

Aerial Work Platform VR Training Simulator Virtual Controls

Operating a boom lift requires proficiency in the real-world. Operators are controlling and moving a platform which they are on. They may be facing away from their target location, and they have extension and other controls to adjust their aerial position. Getting a feel for this is not possible by reading about it. It requires hands-on experience. After using an actual boom lift, whether real or simulated, operators rapidly gain a feel for the machine. In particular, the proportional nature of the controls requires experience in order to master the delicate touch which is most effective. Novice operators will often treat proportional controls as all-or-nothing controllers. After using the training simulator, operators gain an understanding of the delayed effect of proportional controls, and learn not to “over steer”.

JLG Industries Immersive Training Simulator Controls Familiarization

JLG Immersive Training Simulator at Conferences and Expositions

Conexpo-Con/Agg 2020

Augmented World Expo 2018

DevLearn 2017

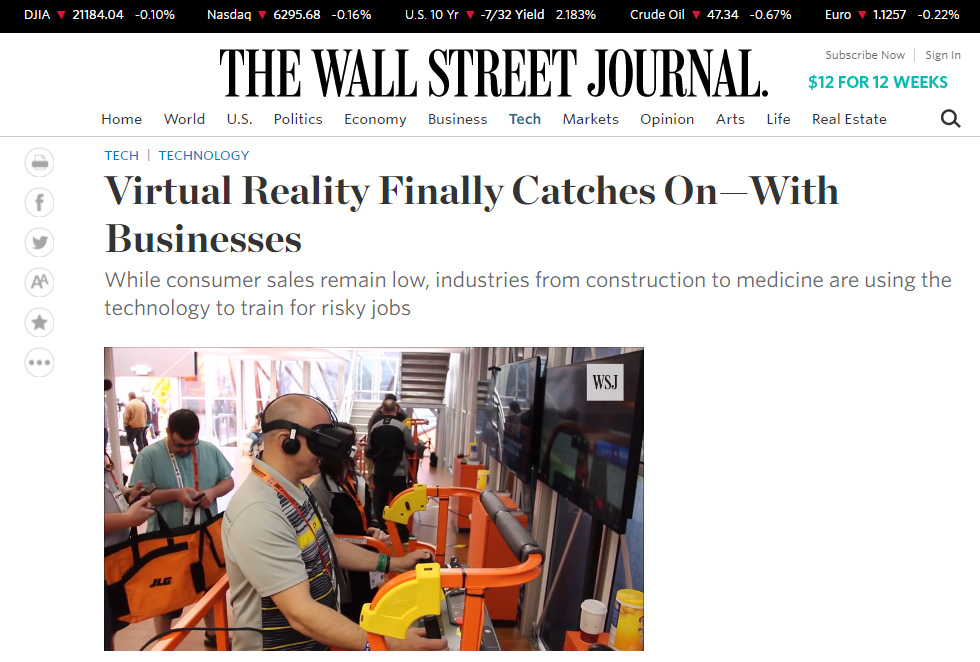

Conexpo-Con/Agg 2017

Unity Vision Summit 2017

JLG Immersive Training Simulator in the News

For Construction Pros 2020

Aviation Pros 2019

Facility Executive 2019

Wall Street Journal 2017

ConstrucTech TV, Safety Zone

JLG Industries, AccessReady XR Training Simulator Image Gallery

A collection of screenshots and images of the JLG AccessReady Fusion XR boom lift training simulator.

Equipment Operator Training Simulators

Thank you for your interest in the JLG access equipment training simulator products developed by ForgeFX for JLG. Please visit the JLG Industries website for more information about all of their equipment and related products, and for more information about the development of a custom training simulator for your company, please contact ForgeFX Simulations to discuss your requirements and receive an estimate.