ForgeFX Simulations developed this aircraft deicing simulator for Global Ground Support, a leading manufacturer of airport ground support equipment used both commercially and by the military. Building upon the success of the initial application of the deicing training simulator built by ForgeFX a decade ago, a next-generation version of the simulator is now available to customers. This next-generation aircraft deicing simulator includes many upgrades and features, including support for virtual reality, multiplayer, VoIP, and more.

Global Ground Support, VR Deicer Simulator

Global Virtual Reality (VR) Deicer Simulator

The training simulation teaches equipment operators year-round to use Global Ground’s Support deicers quickly, with more flexibility and at a lower cost than traditional training. No real-world equipment is taken off the line and no expensive consumables, such as fuel, oil and deicing fluids, are required for simulation-based training.

Global VR Deicer Simulator, Yokota Air Base (YAB), Japan

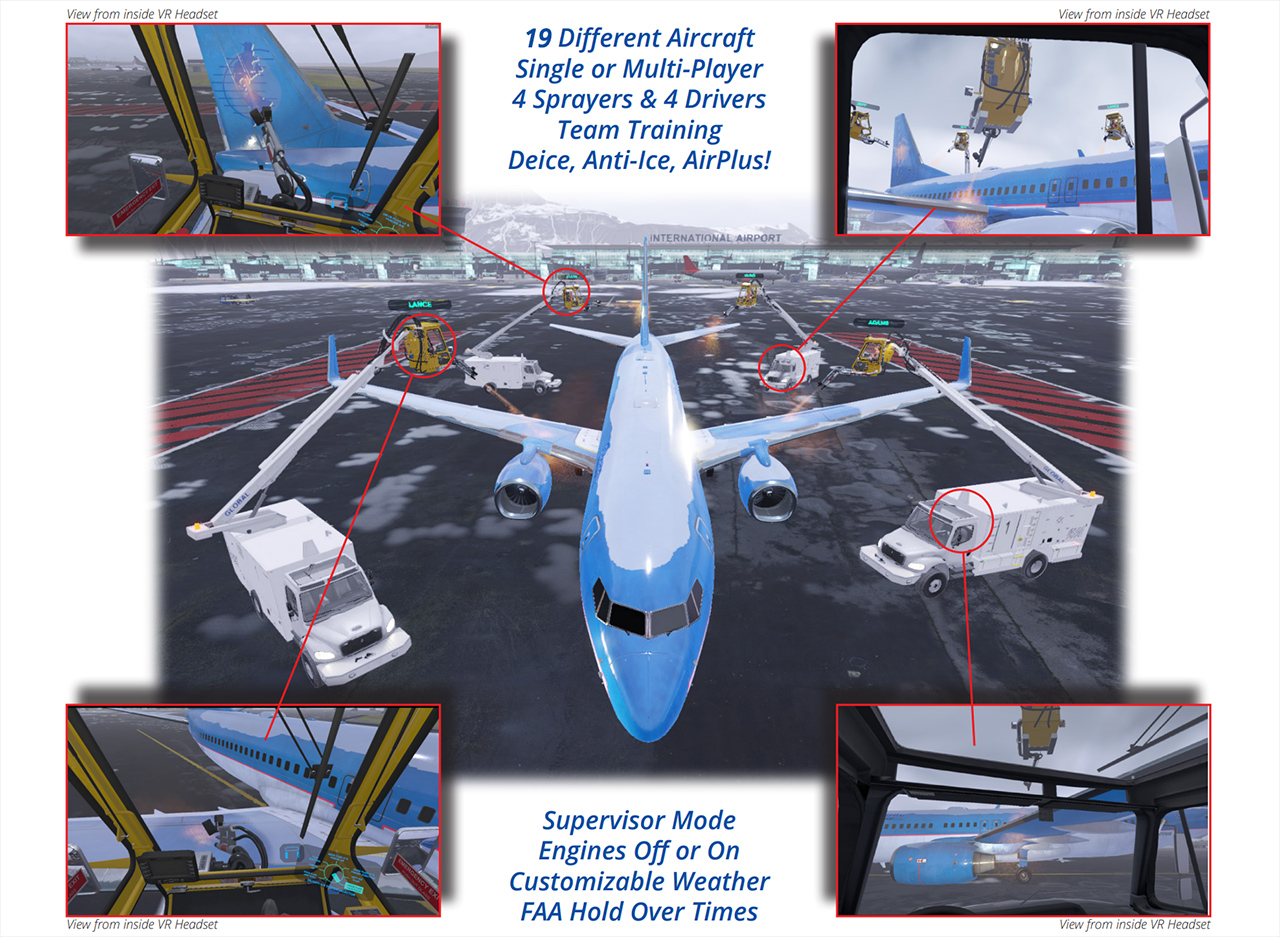

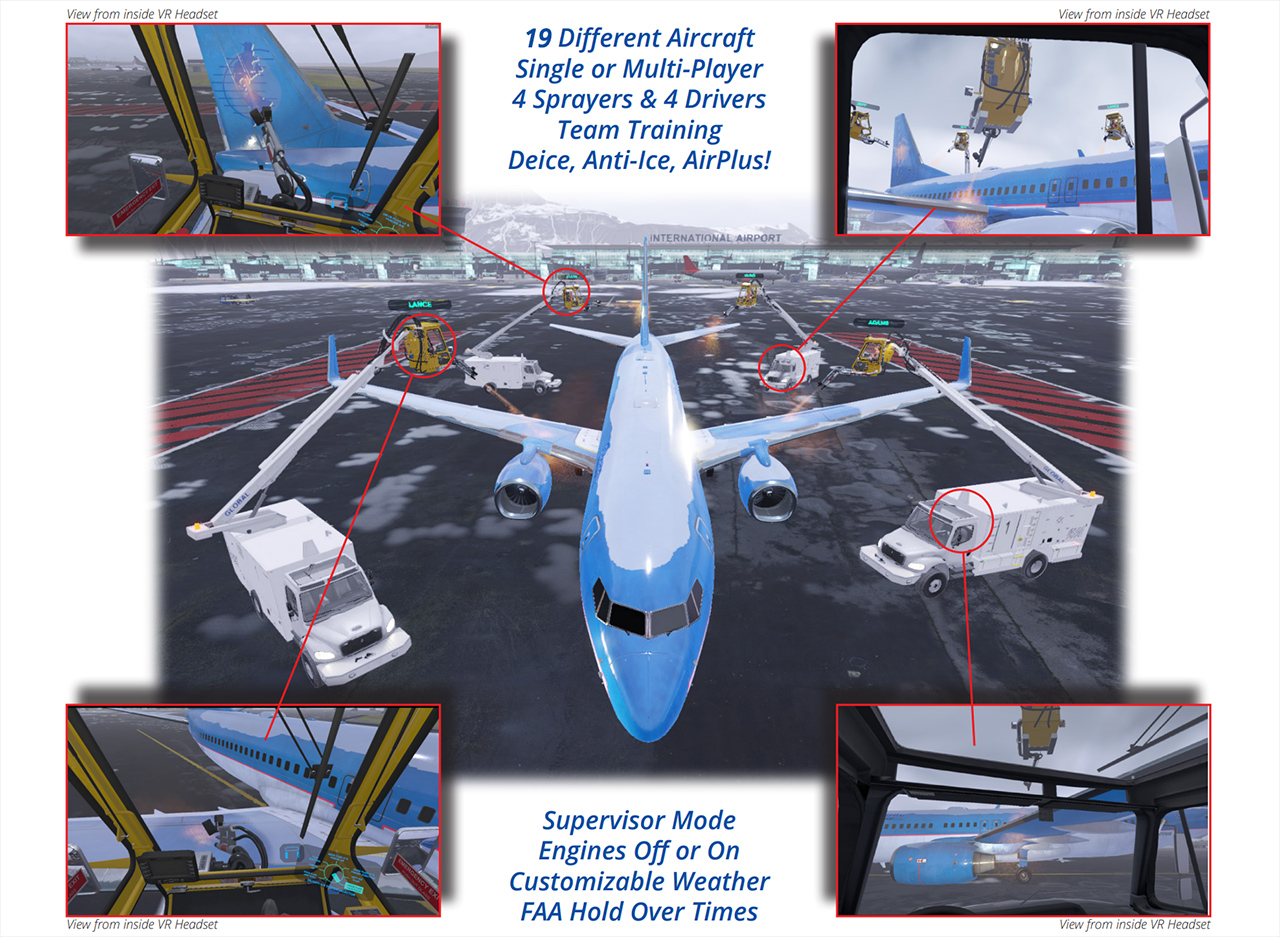

Developed exclusively for the Oculus™ Rift/Meta™ Quest platforms, this immersive training simulator puts you on-board one of three models of a high performing Global deicer, the 2200 Enclosed Cab, 2200 Open Basket or the Extended Reach 2875. Single or multi-user modes for up to 4 drivers, 4 sprayers and 1 observer. Customizable aircraft models, weather conditions and time of day. Train individually or in groups across multiple location.

Meta™ Quest Based Aircraft Deicing Training Simulator

Global Ground Support’s mission is to provide the best in equipment and ground support to get flights in the air on time. Global Ground Support partnered with ForgeFX Simulations to develop this aircraft deicing operator simulator that trains operators in virtual reality, where variables like weather, aircraft, temperature, and precipitation levels are all controllable.

Global Mobile VR Deicer Simulator, by ForgeFX Simulations, for Meta™ Quest.

In addition to supporting integration with the physical controls that operate the real-world equipment, the training simulator platforms includes a portable mobile version. Featuring a compact form factor and minimal footprint, the training simulator station can easily be transported and deployed with minimal effort.

ForgeFX Simulations, Global VR Deicer Simulator, Meta™ Quest 2

The mobile and portable version of Global Ground Support’s VR Deicer Simulator, developed by ForgeFX Simulations, leverages a paired-down version of the physical hardware, a laptop PC, and a Meta Quest 2 headset. This mobile setup offers the same advanced training features as the full simulator, including virtual reality immersion, multiplayer capabilities, and VoIP support, but with enhanced portability and ease of use. The benefits of having a mobile version are significant: it allows training to occur in various locations, including on-site at airports or remote training facilities, providing flexibility and reducing the need for dedicated training spaces. Additionally, this setup is cost-effective, requiring less investment in hardware while still delivering comprehensive, realistic training experiences. The mobility ensures that operators can receive consistent, high-quality training regardless of their location, thereby enhancing overall training efficiency and accessibility.

Global Ground Support VR Deicing Simulator by ForgeFX Simulations

The networked multiuser connectivity of the deicing simulator offers numerous advantages for both trainers and trainees. By enabling collaborative training sessions in virtual reality, the simulator mirrors real-world job scenarios, fostering teamwork and coordination among operators. This interactive environment allows trainees to learn from each other and receive real-time guidance from trainers, enhancing the overall training experience. The collaborative aspect ensures that trainees are well-prepared for the demands of their roles, as they practice and perfect their skills in a setting that closely replicates actual deicing operations.

Virtual Reality Training Simulator for Aircraft Deicing Operator

One of the standout benefits of the networked multiuser support is the ability to connect trainers and trainees regardless of their physical locations. This feature is particularly valuable in the aviation industry, where personnel are often dispersed across various geographical regions. With an internet connection, trainers can conduct sessions with trainees from anywhere in the world, breaking down barriers imposed by distance. This global connectivity not only saves time and travel costs but also ensures that all team members receive uniform, high-quality training, regardless of where they are stationed.

Virtual Reality Aircraft Deicing Simulator

Moreover, the ability to engage in multiuser sessions allows for a more flexible and adaptive training schedule. Trainers can easily organize sessions to fit different time zones and availability, making the training process more accommodating to everyone’s needs. This flexibility ensures that training can be conducted more frequently and efficiently, leading to better preparedness and quicker responses to real-world deicing challenges. Additionally, the collaborative virtual environment fosters a sense of community and shared learning among trainees, promoting a culture of continuous improvement and professional development.

Global VR Deicing Simulator, Support for 19 Different Aircraft

Global VR Training Simulator by ForgeFX Simulations

The Global VR Deicer Simulator, developed by ForgeFX Simulations, features support for the following functionality:

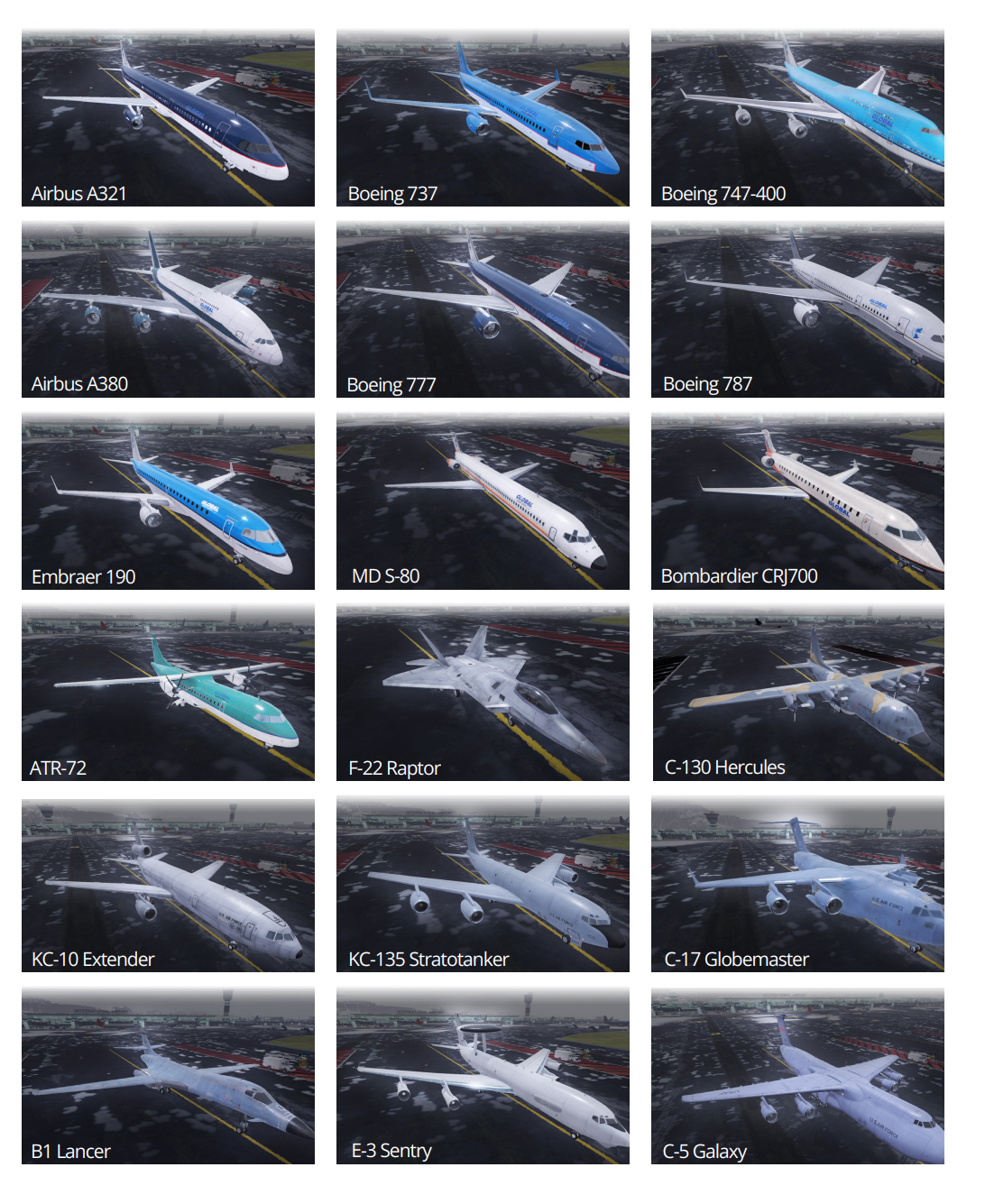

- 19 Different Aircraft

- Single and Multiuser Modes

- Driver and Sprayer Modes

- Team-Based Training

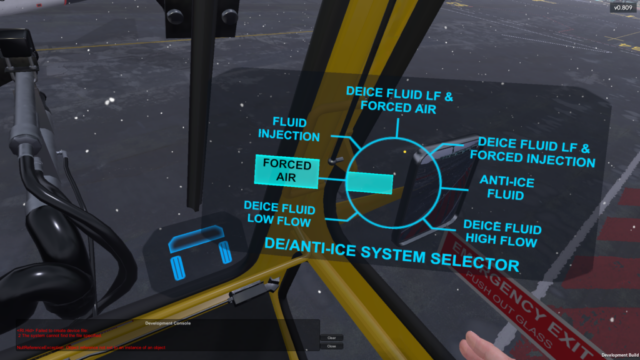

- Deice, Anti-Ice, and AirPlus! Modes

- Supervisor Mode

- Engines Off and On Deicing

- Customizable Weather and Atmospheric Conditions

- FAA Hold Over Times

Virtual Reality Operator Training Simulator

Deicer Simulator Benefits

Simulation-based training ensures that operators are active participants in the learning process, instead of passive audience members merely watching traditional pre-training presentations and videos. Clearly, operators require experiential training, but preferably not with the actual planes or deicing equipment until after they are familiar with the equipment, weather conditions, and procedures.

Training Deicing Operators via a Virtual Reality Training Simulator

This virtual reality based operator training simulator allows operators to become highly familiar and proficient with the real-world controls, in addition to gaining detailed knowledge and understanding of the procedures involved in the entire process.

Operator Training Simulator Performance Analysis

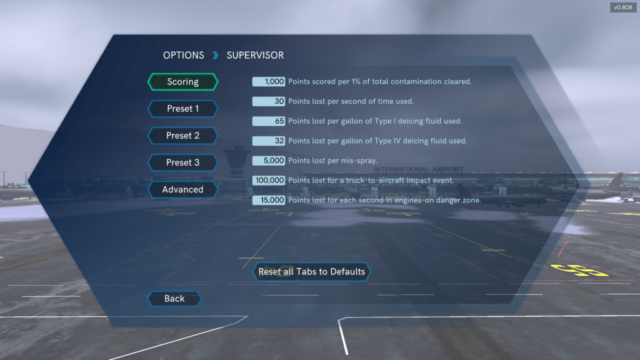

This scoring system also incorporates a high-score board, encouraging operators to compete against each other and have fun while perfecting their efficient execution of proper techniques.

Aircraft Deicing Operator Virtual Reality Training Simulator

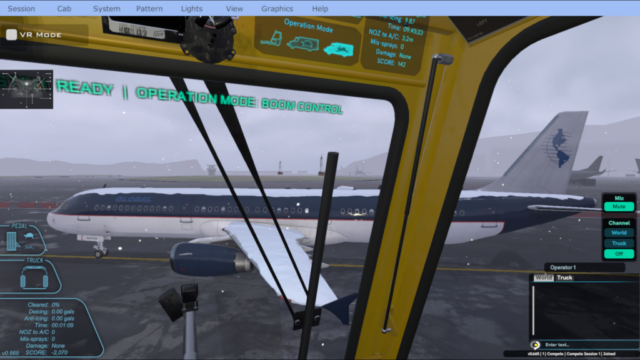

The simulation tracks the performance of users, recording their scores for review by instructors. Users are scored on their performance, including amount of contaminant removed, time taken, gallons of fluid used, no-spray area violations, and aircraft collisions.

Virtual Reality Aircraft Deicing Training Simulator

Current FAA holdover times are active within each simulation session and are applied to the specific weather selection. Timed sessions are compared with fluid usage and applied to each individual aircraft specifications which generates a comprehensive training report for record keeping. Redesigned in 2017 and developed in house by pilots and engineers who have lead the deicing industry for over 25 years

Global VR Training Simulator by ForgeFX Simulations

VR Deicer Simulator in the News

Want more information about this deicing training simulator? Check out these articles:

- Companies Use Latest VR Tech to Train Employees, KCTV 5, August 1, 2019

- A Virtual Deicing Experience, Aviation Pros, June 27, 2017

- Generation 2 VR Deicing Simulator, Aviation Pros, November 1, 2017

- How Virtual Reality Gets Industrial Training Simulators Closer to Real Life Than Ever Before, TechRepublic, May 25, 2016

- Deicing Simulator Saves Fairchild Air Force Base $1 Million, KHQ, February 4, 2016

- Deicing Simulator Improves Training, Saves Air Force Millions of Dollars, Defense Visual Information Distribution Service, January 8, 2016

- New Deicing Simulator Saves Money, Manpower, Increases Training, Fairchild Air Force Base, January 6, 2015

- A Turn to Simulation, Aviation Pros, June 30, 2009

US Air Force Using Aircraft Deicing Simulator

AMC Command Chief Visits Spangdahlem Mobility Airmen

Chief Master Sgt. Shelina Frey, Air Mobility Command command chief, tests out the de-icing simulator at the 726th Air Mobility Squadron at Spangdahlem Air Base, Germany, Feb. 13, 2017. The simulator allows the user to de-ice and anti-ice different types of aircraft under a wide range of weather conditions. Frey visited with AMC Airmen stationed at both Ramstein Air Base and Spangdahlem Air Base, Germany during her visit. The 726th Air Mobility Squadron provides air transportation, cargo, maintenance and enroute support to Allied and American forces.

New Deicing Simulator Saves Money, Manpower, Increases Training

Staff Sgt. Tyler Mousner, 92nd Maintenance Group Maintenance Qualification Training Program instructor, uses the deicing simulator Dec. 3, 2014 at Fairchild Air Force Base, Wash. The simulator was recently installed and will allow Airmen to train without using deicing equipment and use expendable resources. All new, and many currently assigned to the 92nd Aircraft Maintenance Squadron, and some new Airmen to the 92nd Maintenance Squadron will train on the new simulator.

United State Air Forces in Europe and Africa Leadership to Airmen: Cultivate a Culture of Change

Spangdahlem Air Base, Germany – Gen. Frank Gorenc, U.S. Air Forces in Europe and Air Forces Africa commander, operates a deicing simulator on an F-16 Fighting Falcon fighter aircraft during a tour Oct. 18, 2013. Airmen of the 726th Air Mobility Squadron utilize the simulator to increase their proficiency before operating on actual aircraft.

U.S. Air Force photo by Senior Airman Joe W. McFadden / Released

Mobility Squadron Gets it Done in More Ways Than One

Spangdahlem Air Base, Germany – Senior Master Sgt. Brian Rogers, 726th Air Mobility Squadron maintenance superintendent, practices deicing an aircraft using the aircraft deicing simulator inside the AMS maintenance building, Feb. 10. Aircraft deicers are vital to the squadron’s mission in Germany because they enable aircraft to depart on their missions even in freezing weather conditions.

AMS employs more than 100 Airmen to complete its three primary missions of aerial port, command and control, and maintenance. These missions are essential to executing the mobilization of service members and cargo in support of operations in Europe and bases in U.S. Central Command.

Senior Master Sgt. Brian Rogers, 726th Air Mobility Squadron Maintenance Superintendent, practices deicing an aircraft using aircraft deicing simulator

Training Operators in Virtual Reality

Training Deicer Operators

When planes take off in stormy weather, they must be properly deiced to reduce the risk of accidents. In addition, deicing operators must be extremely careful when deicing planes, since any collision between deicing equipment and a plane is costly and can cause flight delays. With stakes as high as these, training highly competent deicing operators is crucial. However, relying solely on traditional training can be expensive and difficult, requiring specific weather conditions and the use of costly consumables. This is where leveraging simulation-based training for aircraft deicer operators comes into play.

Aircraft Deicer VR Simulator – Official Trailer

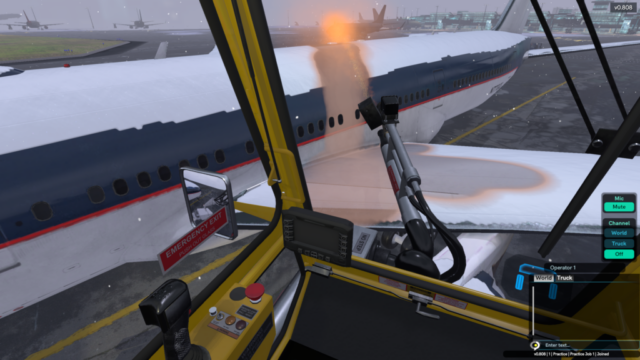

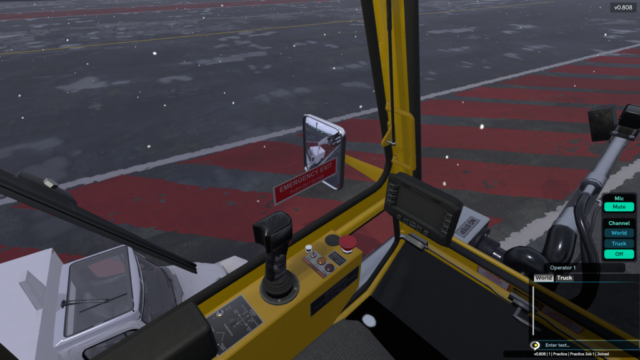

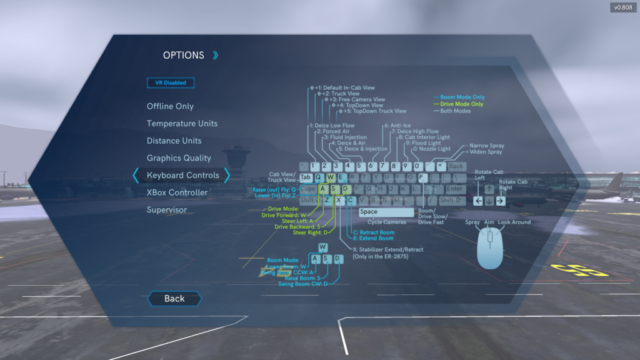

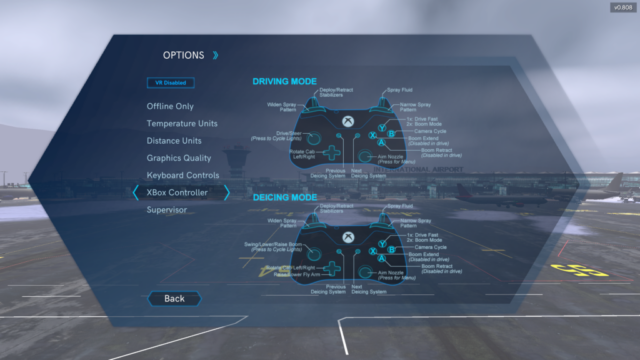

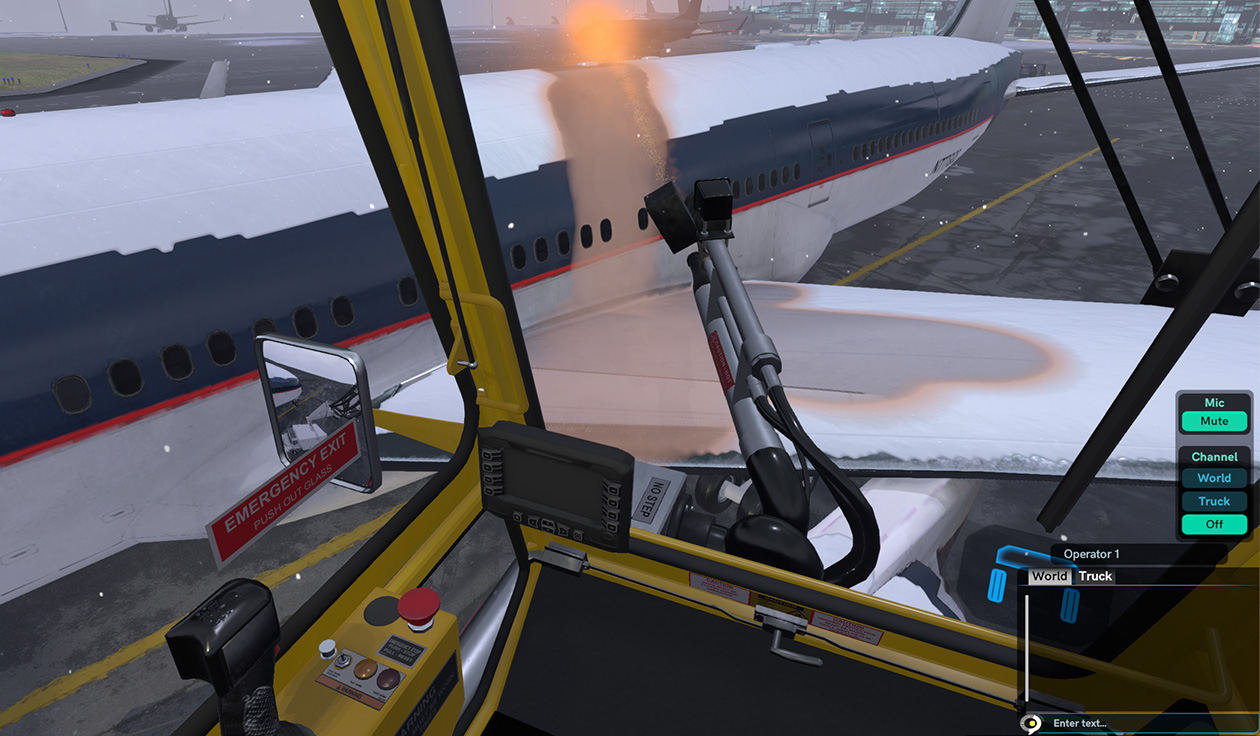

The aircraft deicing simulator that ForgeFX developed for Global Ground Support’s line of aircraft deicers, trains aircraft deicing operators, in virtual reality, for millions of potential training scenarios so that they are prepared for whatever conditions they may encounter in the real-world. The software, coupled with the original equipment manufacturer (OEM) hardware, which includes joysticks, pedals, and a VR headset or wide-screen display, gives the user a first-person perspective of an operator sitting within the cab of the real-world deicer.

Custom Deicing Training Simulator by ForgeFX Simulations for Global Ground Support

The simulation includes a true-to-life real-time fluid rendering system, accurately representing the nozzle and spray dynamics, allowing operators to acquire the necessary finesse to expertly operate the deicer. Training simulation sessions begin by selecting the type of aircraft to be deiced and parameters, including the time of day, wind conditions, temperature, and the type of precipitation present in the environment. The operator has full control over the deicer’s boom arm, cab rotation, truck location, nozzle settings, fluid selection, spray selection and lights.

Deicing Simulator for Global Ground Support by ForgeFX Simulations

Aircraft Deicing Simulator Image Gallery

A collection of screen shot images of the aircraft deicing simulator. Click the forward and back arrows to see images.

What are your training needs?

For an assessment of needs that are specific to your project, please contact ForgeFX Simulations so that we can review your requirements, discuss potential options with you and put forward a software development proposal to achieve your goals.

Contact Us Learn More