Here’s another great example (see: UMWA Coal Mining Training Simulator) of simulations being used in the coal mining industry, but these aren’t operator training simulators. Scientists from the National Energy Technology Laboratory (NETL) are using a supercomputer at the Oak Ridge National Laboratory (ORNL) to simulate the process of coal being converted into carbon monoxide and hydrogen.

This process, known as gasification, happens when coal is subjected to precise temperatures and controlled amounts of oxygen and steam. Through the use of computer-based simulations, scientist hope to reduce the cost and amount of time required to develop zero-emissions power plants.

Chris Guenther, research scientist at NETL’s Computational Science Division discussing the project being conducted at the ORNL:

“This ability to finely resolve relevant structures inside a dense, reactive gas-solid system is not only unique, but also necessary to accelerate the commercial deployment of advanced gasification technology.”

Building Gasifiers via Simulation

Several large scale gasification simulations will be employed for NETL’s Clean Coal Power Initiative, a program that was instituted to address an array of energy issues and accelerate the deployment of advanced technologies to ensure clean, reliable, and affordable electricity for the United States.

NETL Process Dynamic Simulator Research and Training Center

NETL has established a world-class Integrated Gasification Combined Cycle Dynamic Simulator Research and Training Center. The training center is located at the National Research Center for Coal and Energy at West Virginia University.

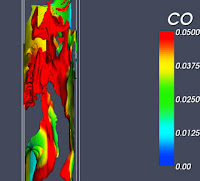

Gasification simulations provides users with accurate 3D information and visualization concerning relevant gasification properties including flow, pressure, temperature, and species distribution. In many cases, the software (which combines fluid dynamics and reaction chemistry for modeling a single functioning unit) produces more information than traditional real-world experiments can provide.

Multiphase Flow with Interphase eXchanges

NETL’s simulation was developed using the Multiphase Flow with Interphase eXchanges (MFiX) framework, an internationally recognized open source software used for modeling gas-solids flow. MFiX allows NETL to simulate hydrodynamics, heat transfer, and the chemical reactions required to change coal into fuel.

MFiX Mass Inlet/Outlet

Scientists can now conduct detailed simulation sessions that will provide accurate predictions on how to more effectively mix coal with oxidizers, thus getting the optimum mix of carbon monoxide and hydrogen. Leveraging knowledge gained from the simulation, more efficient commercial-scale gasifiers can be designed, without having to perform the long and costly series of traditional real-world experiments that are required in order to isolate these important variables.

These gasification simulations are cost-effective and accurate research tools being used for the development of large-scale power plants, and also great examples of how 3D simulations are important components when it comes to planning complex systems. Simulation software is helping to develop power plants and energy systems that will give us clean, reliable, and affordable energy in the future.